Titanium Casting

Titanium Fastener

September 24, 2016

Other Titanium Products

September 25, 2016Material Products

Titanium Bar/Rod

Titanium Tube / Pipe

Titanium Pipe Fitting

Titanium Clad Steel Plate / Sheet / Tube Sheet

Titanium Plate / Sheet

Titanium Elliptical Head / Spherical Head

Titanium Equipment

Titanium Raw Material

Titanium Forging

Titanium Clad Copper Bar / Tube / Wire

Titanium Wire/Welding Wire

Titanium Machining Part

Titanium Fastener

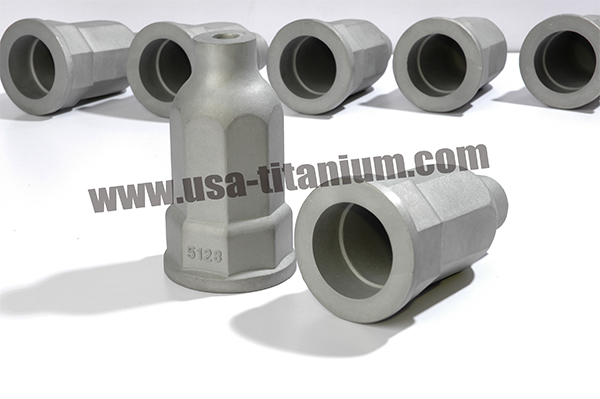

Titanium Casting

Other Titanium Products

Applications:

Per Customer requirements

Technique:

Lost-wax investment casting and lost-foam investment casting are both capable of complicated shapes and small features containing high precision and quality surfaces.Equipment:

Wax injection machines, desiccant rooms, de-wax machines, vacuum melt towers, sinter kiln, and ultrasonic inspection machines.Size:

Per client’s specifications and requirements, from 5g to 30kg.Process:

Wax injecting, slurrying, de-waxing, sintering, casting and furbishing.